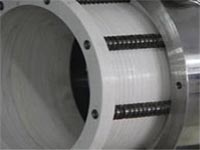

Details of turbine nano grinding mill

For sterile and metal free models

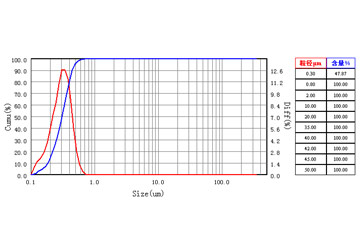

The turbo nano grinder has the same grinding efficiency as the equipment, with good quality repeatability in mass production. It can use grinding media ≥ 0.3mm and is suitable for grinding materials ranging from 1 μ m to 50nm.

In the fields of paint and coatings, lithium batteries, ceramic powders, pharmaceuticals, pesticides, cosmetics, food, etc., the grinding performance is stable and the technology is mature.

NT-X Series Overview/Technical Parameters

Efficient Turbine Nano Grinding Machine NT-X3~50L

NT-X series turbo nano grinder

NT-X series grinding fineness and effect source

The isolation plate grinding chamber can ensure high flow rate and select grinding media with a diameter of 0.3mm or more;

Made entirely of ceramic or PU material, ensuring zero pollution of the material;

The strong grinding of materials by the turbine structure ensures narrow particle size distribution and stable quality, greatly improving production efficiency;

The PLC automation control system can connect the mixers in series to achieve cyclic grinding. Reduce labor costs through programmatic control.

Internal structure diagram display of NT-X series turbine nano grinder

The internal components of the barrel can be assembled into fully ceramic parts or ceramic parts combined with polyurethane parts according to different needs. All components are non-metallic and suitable for grinding materials with no metal pollution and pure color requirements.

NT-X series - characteristics of turbine nano grinding mill

Suitable for continuous nano dispersion and grinding with strict color requirements, such as grinding white

The parts that come into contact with the materials are made of pure oxidized ceramic materials or polyurethane rubber materials, including:

◆ Ceramic bucket body

◆ Ceramic front cover plate

◆ Ceramic sized protective cover

◆ Ceramic separator

◆ Ceramic spacer sleeve

◆ Polyurethane turbine rotor

◆ Polyurethane gasket

◆ Ultra fine nano dispersion grinding suitable for white and solid color materials

NT-X series - characteristics of turbo nano grinding machine

The static multi gap separation system has a total of 10 discharge gaps, with a large material flow area and high production capacity.

Static separation method, the gap can be modulated by 0.05mm, and 0.1mm grinding medium can be added to ensure the grinding effect.

The cylindrical separator is placed at the center of the barrel and can discharge from 360 degrees without any dead corners.

The precision gasket is located between the gaps, and the gap size can be adjusted as needed.

Simply remove the front cover to clean the separator, and one person can independently complete the operation, making cleaning convenient.

The dual turbine rotor design ensures no dead corners, ensuring a large contact range between the rotor and the beads, fully endowing the beads with kinetic energy.

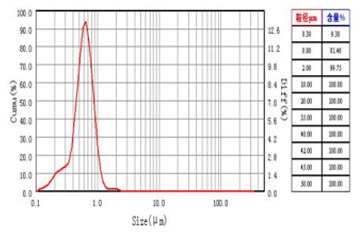

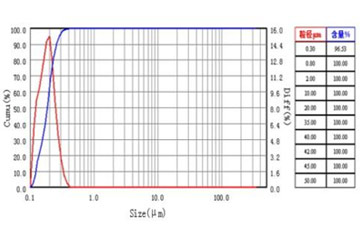

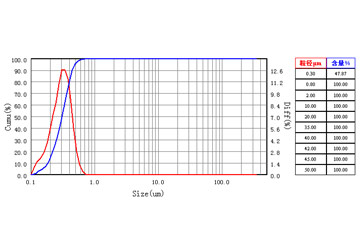

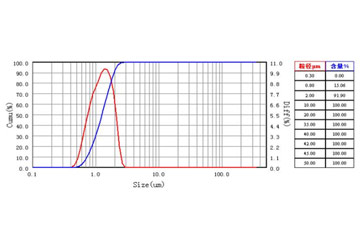

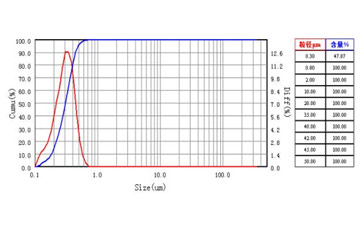

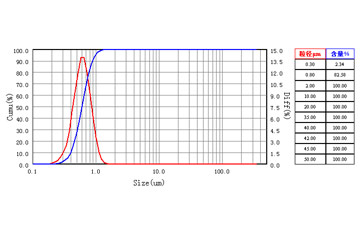

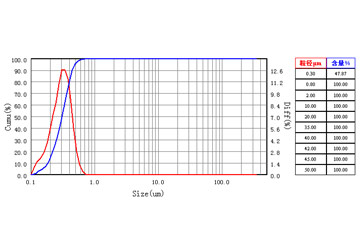

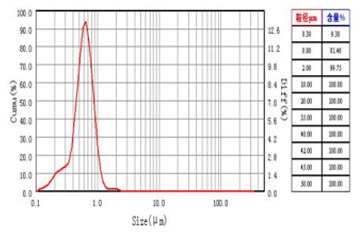

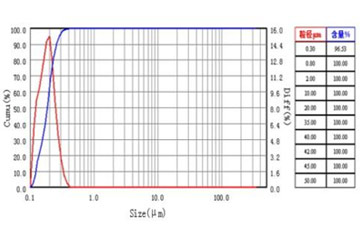

NT-X series - turbo nano grinding machine grinding report display

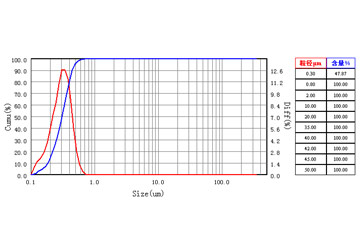

Silicon carbide |

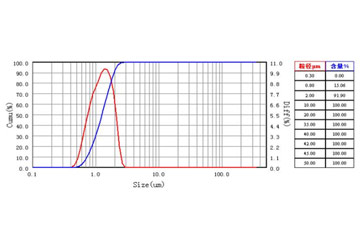

Inkjet inks |

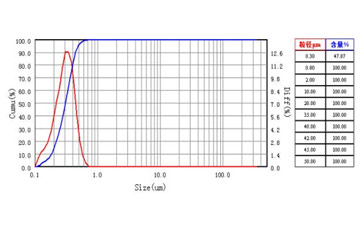

Lithium iron phosphate |

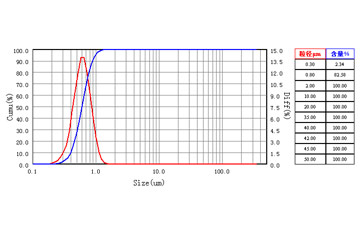

Pesticide suspension agent |

Titanium blue |

Barium titanate |

Glass insulation coating |

Iron aluminum phosphate |

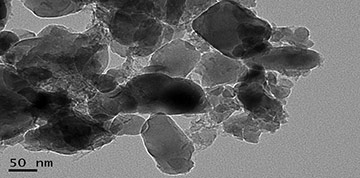

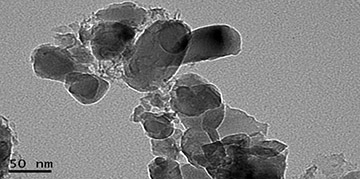

Scanning electron microscopy results of a certain energy material

Application area

◆ Nano ceramic

◆ Zirconia

◆ Lithium battery

◆ Silica sand

◆ Printing inkjet

◆ Aluminum oxide

◆ Food

◆ Variable resistor

◆ Camera ink

◆ Barium titanate

◆ Medicine

◆ Catalyst

◆ Printing ink

◆ Barium carbonate

◆ Cosmetics

◆ PZT