© 2025 Wuxi Xinyang Equipment Technology Co., Ltd. All Rights Reserved.technical support:Wuxi Wangke

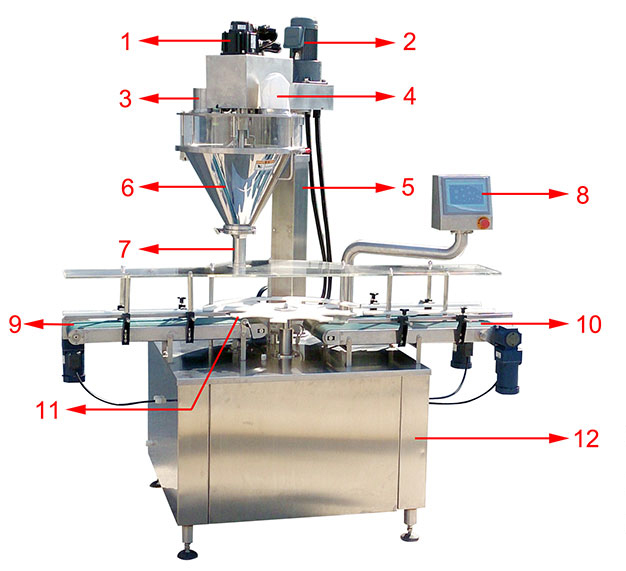

This series of canning machine can complete the work of canning feeding, supporting, filling and metering, weighing and sorting, etc. It can form a complete canning line with other equipment, and is suitable for filling eye shadow powder, glitter powder, pepper powder, pepper powder, milk powder, Rice noodles, protein powder, soy milk powder, etc.

All stainless steel structure; Horizontal opening material box, easy to clean.

Servo motor and servo drive control screw; Servo controlled turntable works with stable performance.

PLC、 Touch screen and weighing module control.

Equipped with a properly positioned height adjustment handwheel, it is convenient to adjust the height of the machine head.

Pneumatic tank support device ensures that materials do not spill out of the container during filling.

Weight sorting device ensures that every product on the assembly line is qualified, eliminating the need for sorting machines in subsequent processes.

Various product parameter adjustment formulas can be stored for future use, with an additional 10 formulas stored.

Replacing spiral attachments can adapt to various materials ranging from ultrafine powder to small particles.

Parameters

| Container size | φ30-130mmφ30-155mm(Enlarged),H50-260mm |

| Canned weight | 10 – 5000g |

| Canned precision | ≤ 500g,≤±1%;>500g,≤±0.5% |

| Canning speed | 20 - 40 bottles/min |

| Power supply | 3P AC208-415V 50/60Hz |

| Compressed air | 6 kg/cm2 0.05m3/min |

| Whole machine power | 2.5Kw |

| Whole machine weight | 350kg |

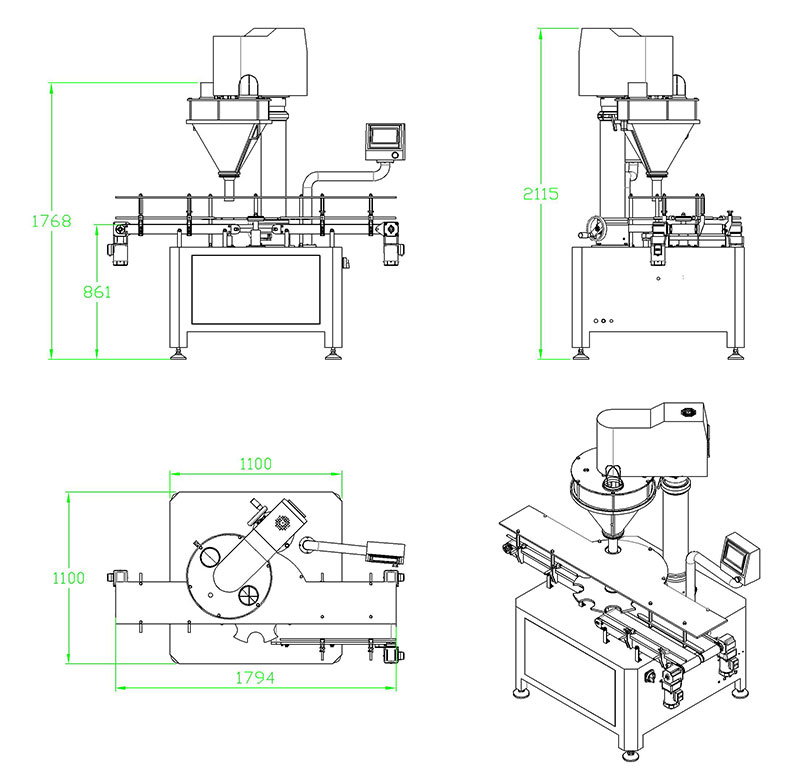

| Whole machine volume | 1800×1100×2100mm |

| Container capacity | 50L |

| Serial number | Name | Model specifications | Origin brand |

| 1 | stainless steel | SUS304 | China |

| 2 | PLC | Siemens Germany | |

| 3 | Touch screen/HMI | Siemens Germany | |

| 4 | Filling servo motor | 1KW | Panasonic servo motor |

| 5 | Fill servo drive | 1KW | Panasonic servo drive |

| 6 | Rotary servo motor | 750W | Panasonic servo motor |

| 7 | Rotary servo drive | 750W | Panasonic servo drive |

| 8 | Mixing deceleration motor | 400W | Taiwan Yuxin |

| 9 | solenoid valve | Airtac | |

| 10 | cylinder | SDA40X15 | Airtac |

| 11 | Filter-regulator | AFR-2000 | Airtac |

| 12 | Small power motor | 120W 1300rpm Model: 90YS120GY38 | Taiwan JSCC |

| 13 | Reducer | Ratio:1:36,Model:90GK(F)36RC | Taiwan JSCC |

| 14 | power switch | HZ5BGS | Wenzhou Changxin |

| 15 | Circuit breaker | schneider | |

| 16 | emergency stop switch | schneider | |

| 17 | filter | ZYH-EB-10A | Beijing Zhongyuhao |

| 18 | AC contactor | CJX2 × 1210 | Wenzhou Zhengtai |

| 19 | thermal relay | NR2-25 | Wenzhou Zhengtai |

| 20 | dc relay | MY2NJ 24DC | Omron Japan |

| 21 | switch power supply | Changzhou Chenglian | |

| 22 | AD weighing module | High speed module | |

| 23 | Load cell | 5KG | Mettler |

| 24 | photoelectric sensor | BR100-DDT | Autonics |

| 25 | Material level sensor | CR30-15DN | Autonics |

| Serial number | Name | Model | Unit | Quantity | Notes |

| 1 | Dumb wrench | branch | 2 | tool | |

| 2 | Adjustable wrench | branch | 2 | tool | |

| 3 | allen key | cover | 1 | tool | |

| 4 | cross screwdriver | grasp | 2 | tool | |

| 5 | A screwdriver | grasp | 2 | tool | |

| 6 | socket | only | 1 | attachment | |

| 7 | Pressure plate | only | 1 | attachment | |

| 8 | weight | 1000G | individual | 1 | attachment |

| 9 | spiral | cover | 1 | attachment | |

| 10 | operation instructions | share | 1 | file |

Tel

QR code

QR code

Top