Product details

High speed circulating rod type nano sand mill NTV series circulating sand mill nano sand mill

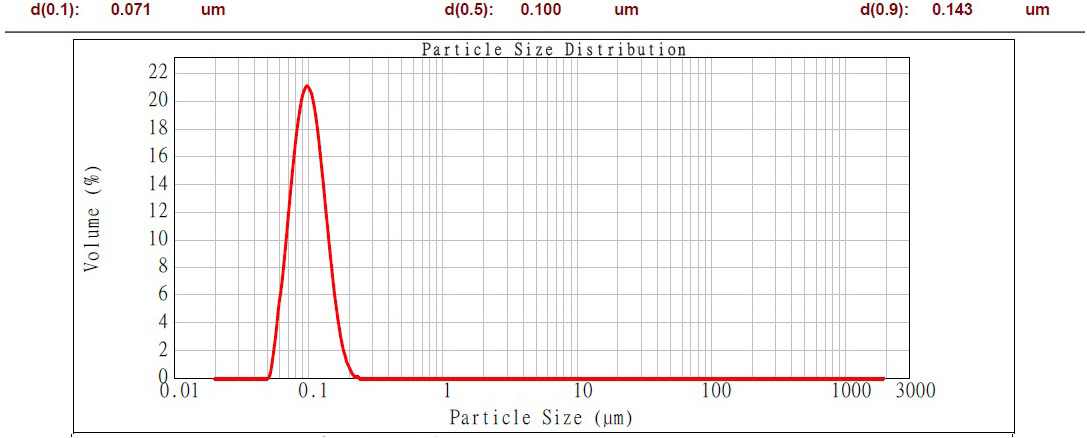

Suitable fineness: 2um-30nm

Grinding size: ≥ 0.05

This model is flexible to use, easy to clean, simple to maintain, has high sanding efficiency, large output, low energy consumption, and simple control.

Technical parameter

|

Model |

Experimental level |

Mass production grade |

|

NT-0.3L |

NT-0.6L |

NT-1L |

NT-V6 |

NT-V10 |

NT-V30 |

NT-V60 |

NT-V150 |

NT-V300 |

|

Magnification factor [l] |

- |

- |

0.08 |

0.2 |

0.5 |

2 |

4 |

8 |

|

|

Sand grinding chamber capacity [l] |

0.6 |

0.6 |

1 |

6 |

10 |

30 |

60 |

150 |

300 |

|

Good sanding batch [l] |

0.3-1 |

1-2 |

2-10 |

100-600 |

100-500 |

500-2000 |

>2000 |

>4000 |

>7000 |

|

Flow rate [kg/h] |

10-50 |

100-300 |

180-380 |

40-200 |

100-500 |

500-2500 |

1000-6000 |

2000-1500 |

5000-20000 |

|

Power [kw] |

0.75 |

2.2 |

3.7 |

15 |

22 |

45 |

75 |

160-200 |

315 |

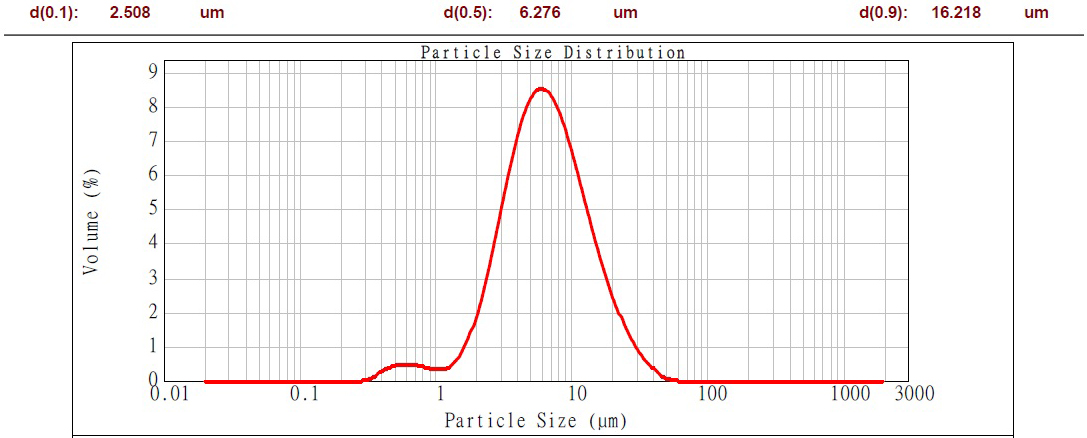

Brown pigments (various oxides)

|

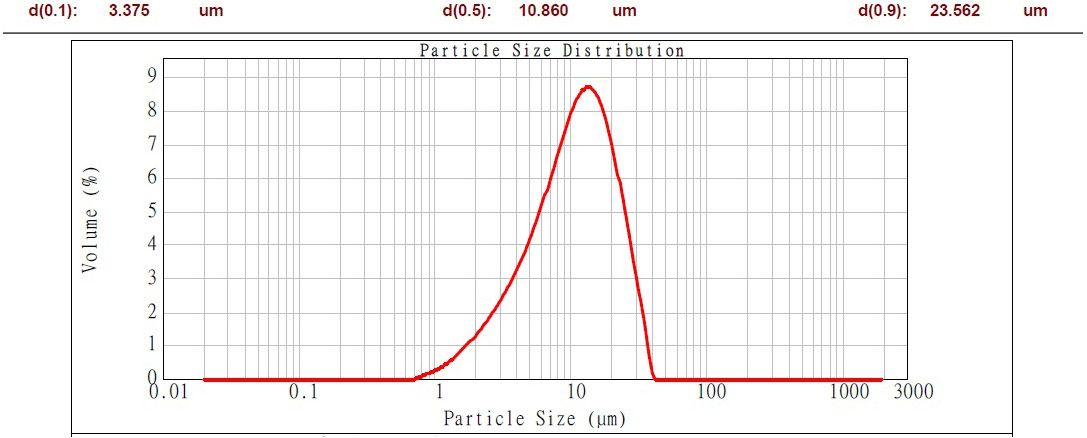

Before sanding

|

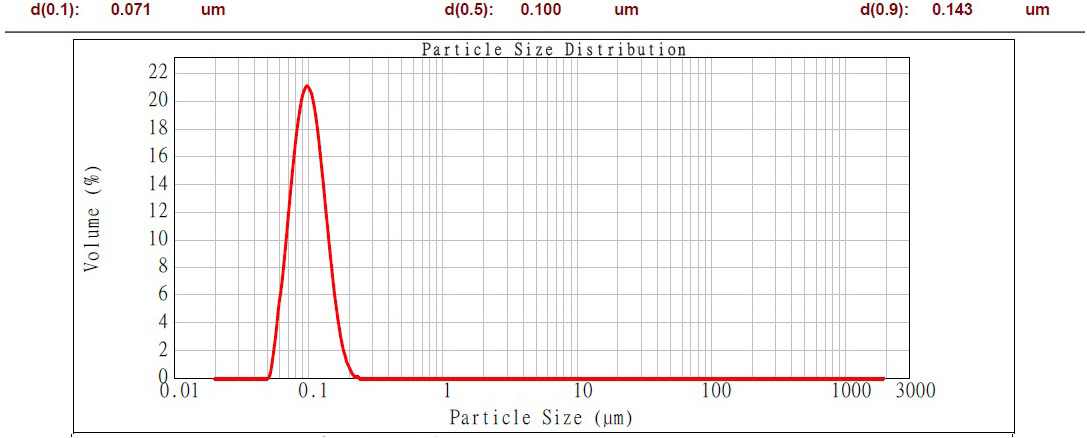

After sanding: the dispersion rate is only 0.6

|

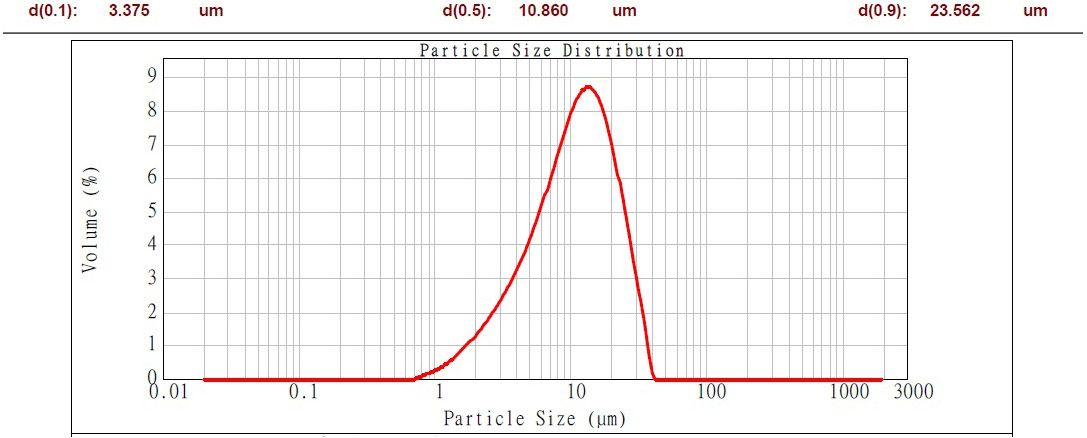

Metal

Before sanding

|

After sanding

|

Design Philosophy - Six Skills to Benefit You

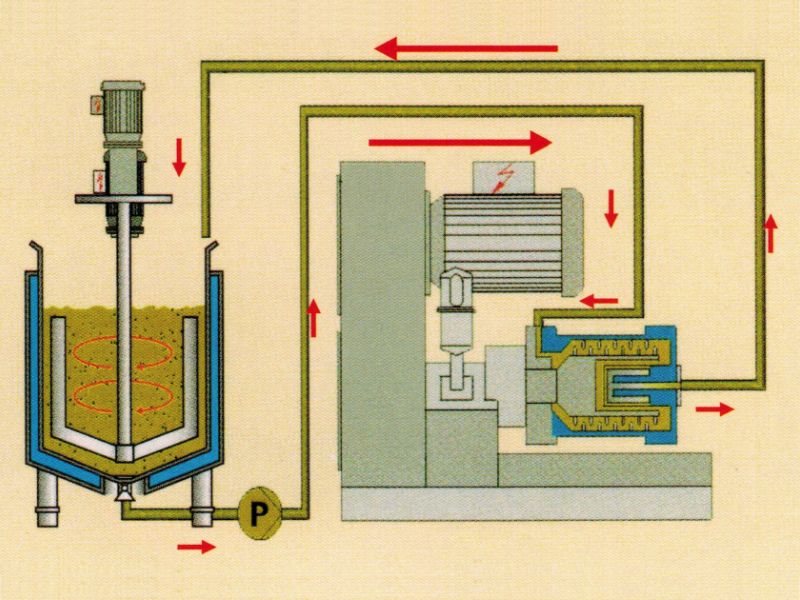

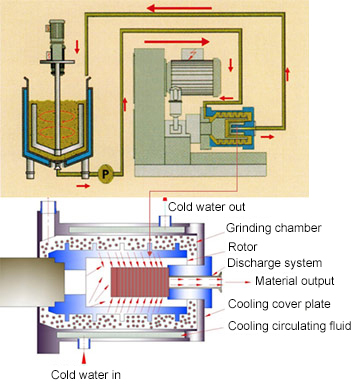

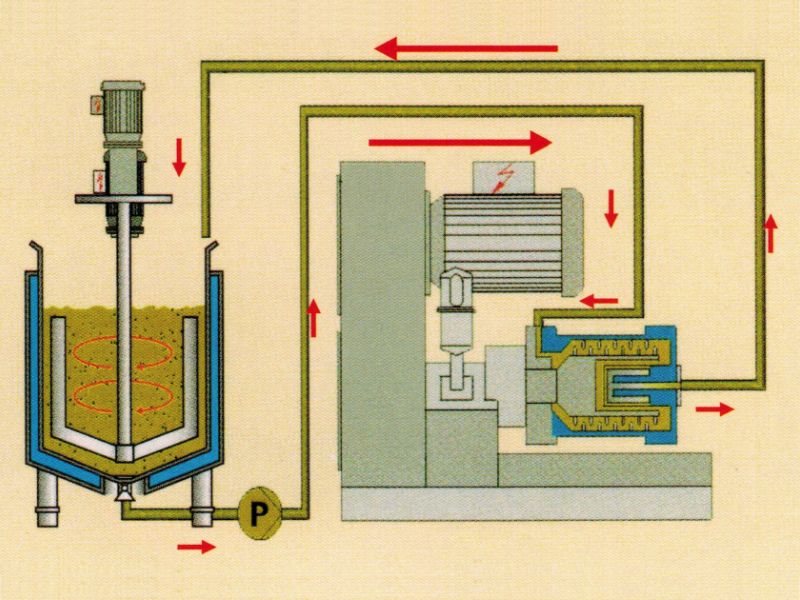

Specialty 1 can achieve high flow circulation sand grinding

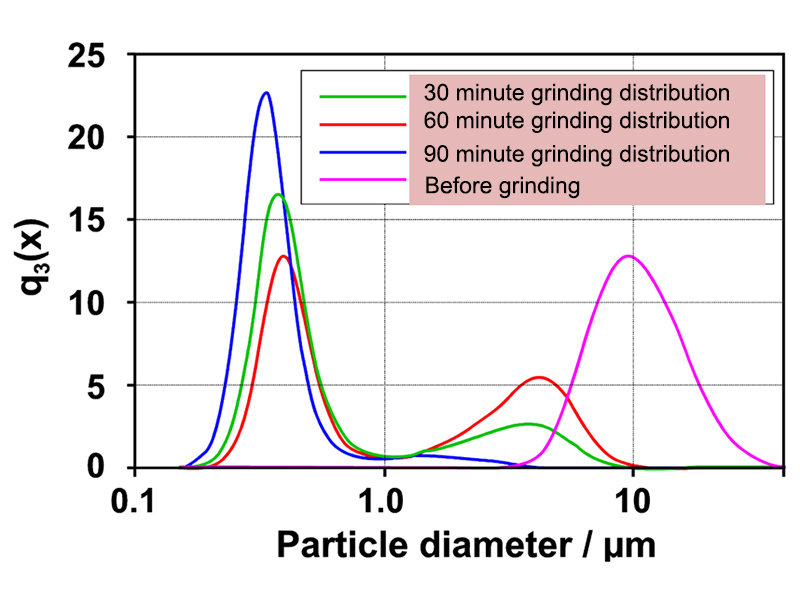

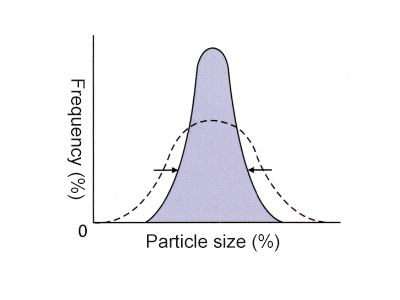

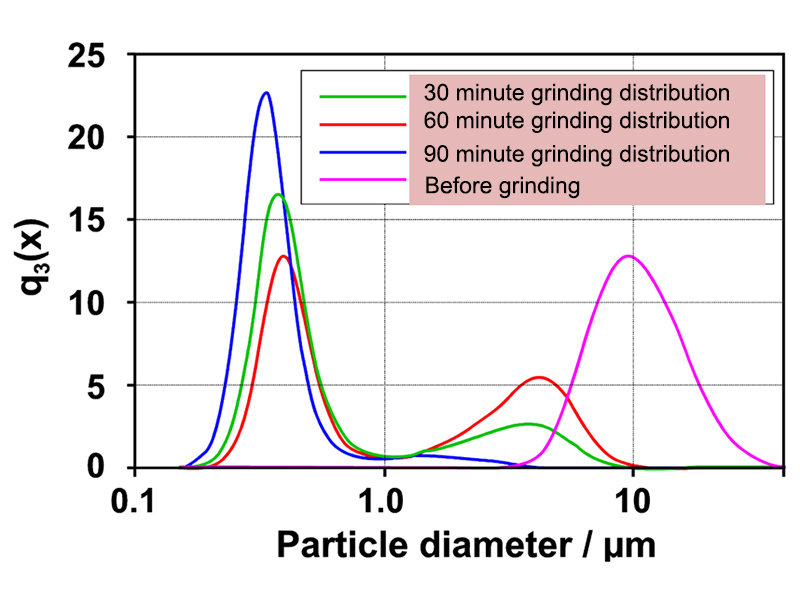

The energy of sand grinding is concentrated, and all materials are ground in the sand grinding zone, resulting in a narrow particle size distribution of the obtained materials; The slurry in the mixing tank and disperser circulates at a large flow rate, so the slurry can circulate dozens of times in a short time and process materials in large quantities.

Particle size distribution |

Can be continuously sandblasted and dispersed |

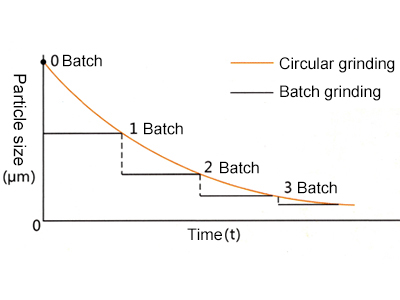

Compared to traditional mills, it can achieve a concentrated particle size distribution even at the same average particle size.It can achieve automatic cyclic sanding.Setting the parameters for cyclic sanding can achieve automatic cyclic sanding without the need for manual intervention.

Over time, dispersion will enable your product to reach the target granularity. Low temperature sanding can be achieved. Shorten the retention time of the slurry in the grinding chamber and effectively suppress temperature rise. Low temperature sand grinding can be achieved through the cooling of circulating cooling water.

Simple configuration

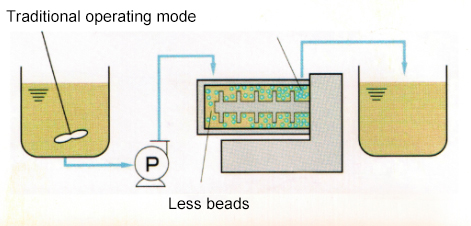

The operation mode of traditional grinding machines

1. Difficult to control particle size and insufficient dispersion;

2. The particle size distribution is often wide;

3. Unable to control the temperature of the material;

4. During high flow and high-speed operation, the grinding medium is prone to accumulate on one side of the chamber and block the discharge port.

Special Feature 2: High Energy Sand Grinding

Uniform energy distribution

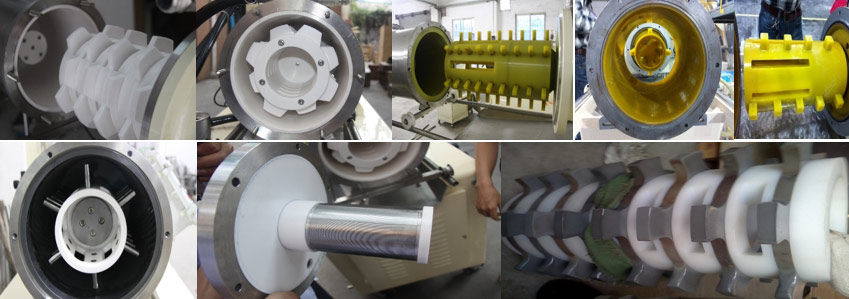

Special feature 3 supports tiny grinding beads

Use a dynamic separation screen to achieve stable separation of small grinding media and slurry.

Specialty 4: structurally similar

The structural principles of small and large machines are similar

Special Feature 5: Good Cooling Effect

There is a specially designed cooling structure inside the sanding chamber

Special feature 6: The liquid receiving part can be made of various materials

We can customize material solutions according to user requirements.

The discharge area is large, which is 2-4 times that of disc and turbine machines. The material has good passability and is not easy to block the machine. It has outstanding advantages in producing expandable materials. The cooling and heat exchange effect is good. The cooling area of the barrel, rotor, and discharge device is 1.3-1.5 times that of disc and turbine equipment, effectively controlling the temperature rise of materials.

Application area

NTV series high-efficiency rod type nano sand grinder - well produced and widely used

Applied to: water-soluble products, oil soluble products, pollution-free products, alcohol products, suitable for machinery and engineering in different industries and applications.

Provide equipment and engineering services for the following industries in the Sand Grinding and Dispersion Division

Lithium battery positive/negative/separator alumina

Ceramic ink, ceramic pigment, nano color paste

Calcium carbonate, zirconium silicate, zirconium oxide cosmetics

Printing Ink Inkjet Ink Thermal Transfer Inkjet

Aluminum hydroxide pesticide suspension agent aluminum silver paste

Polishing agent (CMP) liquid crystal display (LCD)

Electronic paste magnetic materials

Silicon dioxide graphene food additive

Aerospace nanomaterials, magnetic materials, conductive slurries

Biopharmaceutical cell lysis leather plastic materials