Product details

The continuous mixing machine is a fast and high productivity mixing machine that operates continuously from the entry, mixing, homogenization to discharge of materials, without interruption, achieving a large mixing volume within a small product retention time. It is a continuous mixing equipment required for continuous production on assembly lines. Mainly used in the mixing of solid solid (powder to powder) and solid liquid (powder to liquid) in flammable and explosive industries. The application industries include chemical, food, pharmaceutical, coal, metallurgy, ceramics, pigments, dyes, insecticides, etc. Applicable materials include laundry detergent, food, oil coating for carbon black, spice coating for talc powder, refractory materials, flammable and explosive materials, grinding materials, carbon, fertilizers, drugs, seasonings, salt, wood powder and clay, chemical products, etc.

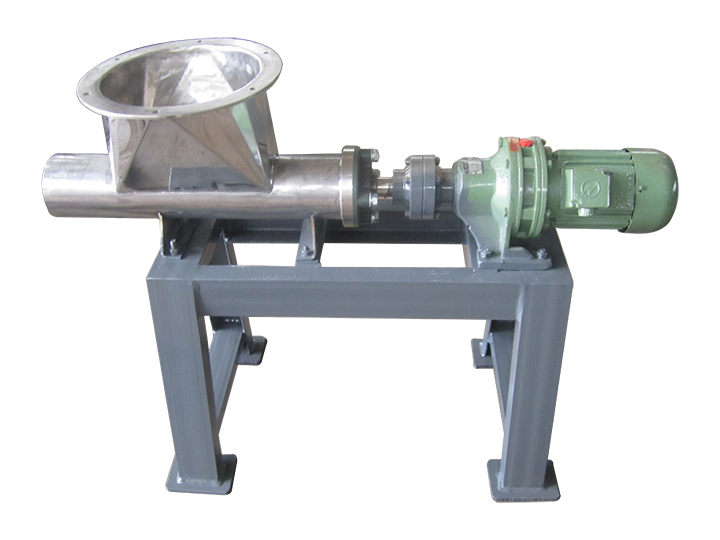

Continuous mixing machine feeding device

Equipped with elevated continuous mixing machine

Product features

1. Can meet the requirements for material mixing and continuous production.

2. By relying on the staggered arrangement of mixing spiral blades installed on the inner wall of the cylinder, a unique splitting and combining motion is provided, allowing the material to be thrown and flipped back and forth inside the cylinder within a short retention time, thereby generating backflow mixing of the material. This spiral blade ensures that the mixing motion of the mixer is gentle and does not cause material breakage.

3. According to user requirements, a variable frequency speed regulation device can be equipped to determine the product's retention time and productivity.

4. Add a jacket and spray device according to user requirements to heat, cool, or spray an appropriate amount of liquid into the material. At the end of the discharge, there is a specially designed discharge overflow plate, which forms a retention volume for the material in the cylinder and flows out from the overflow plate. When complete discharge or cleaning is required, the cylinder can be reversed to remove the material from the mixer.

5. The continuous mixer can be installed on a flat ground or steel frame and must be fastened with bolts; During installation, use a level to measure the surface of the foundation. A straight pipe should be installed under the discharge port of the mixing machine to ensure smooth discharge and prevent blockage of the material into the machine, which may cause blockage.

6. The feed should be stable. Spiral conveyors can be used for feeding to ensure that the materials meet the proportioning requirements and are evenly fed into the mixer, ensuring consistent product quality after mixing. The suction port must draw in air with low wind speed to maintain a slight negative pressure inside the machine and prevent the suction of material powder.

All stainless steel continuous mixing machine