© 2025 Wuxi Xinyang Equipment Technology Co., Ltd. All Rights Reserved.technical support:Wuxi Wangke

This series of canning machine can complete the work of canning feeding, supporting, filling metering, weighing and sorting, etc. It can form a complete canning line with other equipment, and is suitable for filling eye shadow powder, glitter powder, pepper powder, pepper powder, milk powder, Rice noodles, protein powder, etc.

| Container size | φ50-150mm, H 50-300mm |

| Canned weight | 10 – 5000g |

| Canned precision | ≤ 500g,≤±1%;>500g,≤±0.5% |

| Canning speed | 15 - 40 bottles/min |

| Power supply | 3P AC208-415V 50/60Hz |

| Compressed air | 6 kg/cm2 0.05m3/min |

| Whole machine power | 1.6Kw |

| Whole machine weight | 300kg |

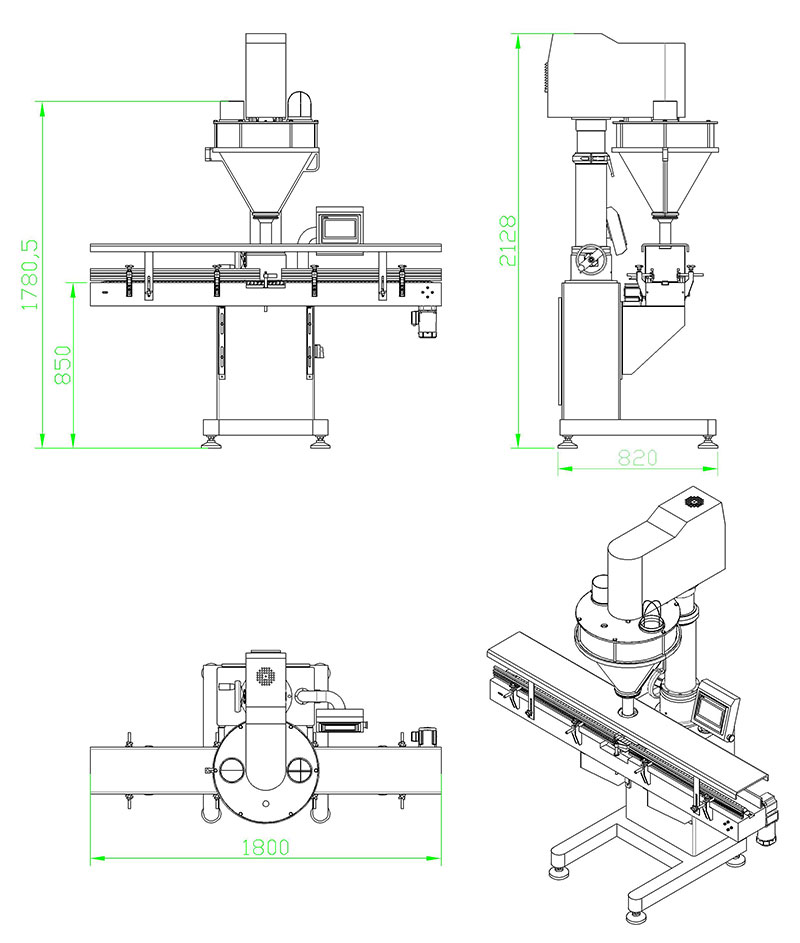

| Whole machine volume | 2150×820×1800mm |

| Container capacity | 50L |

| Serial Number | Name | Model specifications | Origin brand |

| 1 | stainless steel | SUS304 | China |

| 2 | PLC | Siemens Germany | |

| 3 | Touch Screen | Siemens Germany | |

| 4 | Filling servo motor | ECMA-C20807RS | Delta |

| 5 | Fill servo drive | B2721BW3450680 | Delta |

| 8 | Mixing deceleration motor | 400W | Taiwan Wanxin |

| 9 | solenoid valve | Airtac | |

| 10 | Tank cylinder | SDA40X15 | Airtac |

| 11 | Can stop cylinder | MA20X25 | Airtac |

| 12 | Shield cylinder | TN16X20 | Airtac |

| 13 | Filter-regulator | AFR-2000 | Airtac |

| 14 | Small power motor |

120W 1300rpm Model: 90ys120gy38 |

Taiwan JSCC |

| 15 | Reducer |

Ratio:1:36 Model: 90GK(F)36RC |

Taiwan JSCC |

| 16 | power switch | HZ5BGS | Wenzhou Changxin |

| 17 | Circuit breaker | schneider | |

| 18 | emergency stop switch | schneider | |

| 19 | filter | ZYH-EB-10A | Beijing Zhongyuhao |

| 20 | AC contactor | CJX2 × 1210 | Wenzhou Zhengtai |

| 21 | thermal relay | NR2-25 | Wenzhou Zhengtai |

| 22 | dc relay | MY2NJ 24DC | Omron Japan |

| 23 | Switching power supply | Changzhou Chenglian | |

| 24 | photoelectric sensor | BR100-DDT | Autonics |

| 25 | Material level sensor | CR30-15DN | Autonics |

| 26 | Load cell | 5KG | Mettler |

Tel

QR code

QR code

Top