© 2025 Wuxi Xinyang Equipment Technology Co., Ltd. All Rights Reserved.technical support:Wuxi Wangke

This machine is mainly developed and designed for ultra-fine powders that are prone to dust and high-precision packaging requirements. It completes dual speed filling, metering, and lifting work based on the signal provided by the weight sensor installed under the container.

A weight sensor is installed under the container tray to perform fast and slow filling according to the pre-set weight, ensuring high packaging accuracy.

The servo motor drives the tray to lift and lower, and the lifting speed can be set arbitrarily. During filling, there is basically no dust flying out and polluting the environment.

Servo motor and servo drive control screw, with stable performance and high precision.

PLC control, touch screen human-machine interface display, easy to operate.

All stainless steel structure; Combination material box, easy to clean.

The filling head is equipped with a handwheel to adjust the height, making it easy to achieve packaging of various specifications.

The fixed screw installation structure will not affect the material properties during filling.

Workflow: Manual bagging or canning → Container lifting → Rapid filling while container lowering → Weight reaching the predetermined value → Slow filling → Weight reaching the target value → Manual container retrieval.

Pneumatic bag clamping device and can support device are available for selection, just choose different devices to meet the requirements of canning and bagging.

Parameters

| Package weight | 10kg - 30kg |

| Packaging accuracy | ≤±0.1-0.2% |

| Packaging speed | 1-3 times/minute |

| Power supply | 3P AC208 - 415V 50/60Hz |

| Whole machine power | 6KW |

| Whole machine weight | 700kg |

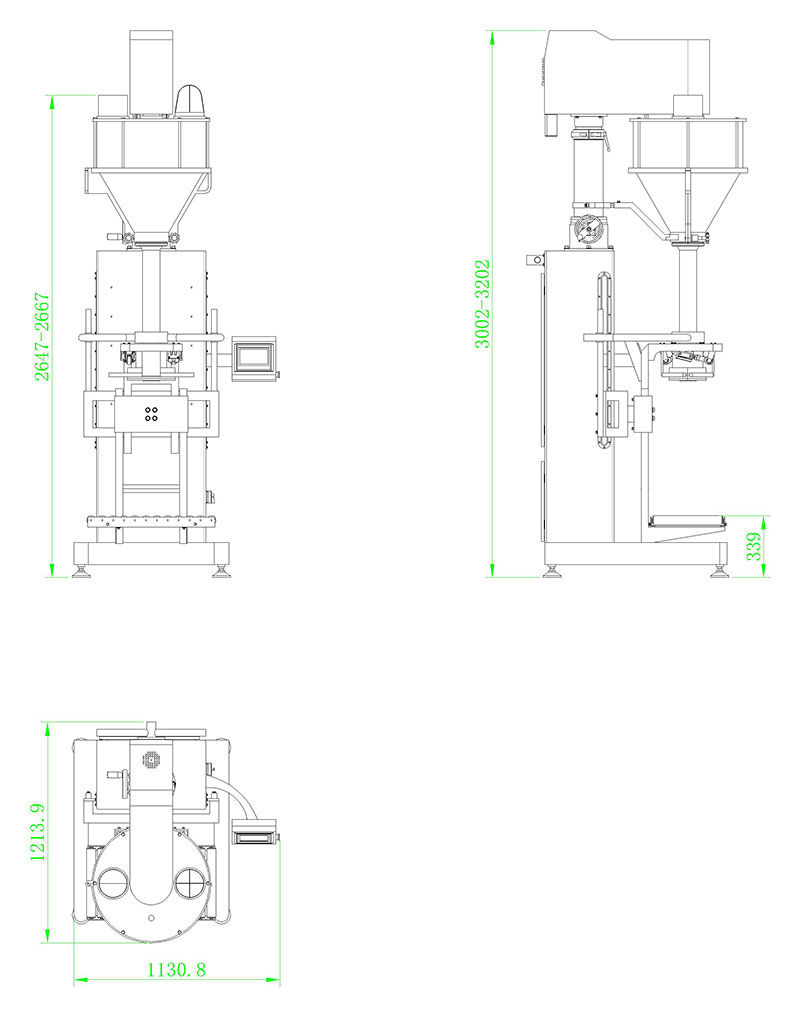

| Whole machine volume | 1135×980×3200mm |

| Container capacity | 80 L |

| Serial Number | Name | Model specifications | Origin brand |

| 1 | stainless steel | SUS304 | China |

| 2 | PLC | Siemens Germany | |

| 3 | Touch Screen | Siemens Germany | |

| 4 | Filling servo motor | 3KW | Panasonic |

| 5 | Fill servo drive | 3KW | Panasonic |

| 6 | Mixing deceleration motor | 1.5KW | Taizhou Tsinghua Ziguang |

| 7 | solenoid valve | Taiwan Xin Gong | |

| 8 | cylinder | MA50X50 | Airtac |

| 9 | Lift servo motor | 1.5KW | Panasonic |

| 10 | Lift servo drive | 1.5KW | Panasonic |

| 11 | Lift reducer | RV50/7.5 | Shanghai Saini |

| 12 | power switch | HZ5BGS | Wenzhou Changxin |

| 13 | Circuit breaker | schneider | |

| 14 | emergency stop switch | schneider | |

| 15 | filter | ZYH-EB-10A | Beijing Zhongyuhao |

| 16 | AC contactor | CJX2 × 1210 | Wenzhou Zhengtai |

| 17 | thermal relay | NR2-25 | Wenzhou Zhengtai |

| 18 | dc relay | MY2NJ 24DC | Omron Japan |

| 19 | switch power supply | Changzhou Chenglian | |

| 20 | Load cell | IL150 | Mettler Toledo |

| 21 | photoelectric sensor | BR100-DDT | Autonics |

| 22 | Material level sensor | NL-2000 | Shanghai Yahong |

| 23 | frequency converter | VFD-015EL(1.5KW)380V | Delta |

| Serial Number | Name | Model | Unit | Quantity | Notes |

| 1 | Wrench | branch | 2 | tool | |

| 2 | Adjustable wrench | branch | 1 | tool | |

| 3 | allen key | cover | 1 | tool | |

| 4 | cross screwdriver | grasp | 2 | tool | |

| 5 | A screwdriver | grasp | 2 | tool | |

| 6 | Foot switch | only | 1 | attachment | |

| 7 | socket | only | 1 | attachment | |

| 8 | Pressure plate | only | 1 | attachment | |

| 9 | weight | 10KG | individual | 1 | attachment |

| 10 | spiral | cover | 1 | attachment | |

| 11 | operation instructions | share | 1 | file |

Tel

QR code

QR code

Top